The story of Harris Tweed is one of a remote island community that lies between the Highlands of Scotland on the north west tip of Europe and the North Atlantic Ocean. I have lusted over this truly unique fabric and have longed to visit the beautiful setting in which it is created for some time now. Thankfully, the launch of the Nike Air Royalty Harris Tweed meant that myself and Susie were invited up by the sportswear giant. So, after traveling up to Glasgow we hopped on to an unnervingly small Flybe plane to be taken to the Isle of Lewis capital, Stornaway. From the comfort of our room in Braighe House, we watched the as the super strong winds, rain and sea spray beat down down on the window. Fortunately, the weather improved enough the following morning to enable Lorna Macualey of the Harris Tweed Authority to talk us through the creation process. I eagerly followed and snapped away at each well honed and practiced process from start to finish, documenting the intriguing relationship of mill and weaver. I should warn you, the below post is an epic one so why not make yourself a cup of tea and read on...

The Harris Tweed Centenary Label. Celebrating one hundred years of the Orb.

Before I offer an abundance of 'factory porn' and talk you through the processes of what makes Harris Tweed so special, I have to acquaint you with the brand and give you a little background. It is arguably the most famous textile in the world. It is certainly the only cloth that is protected by an act of parliament. The Harris Tweed Authority took over from the Harris Tweed Association in 1993 by Act of Parliament. Thus the definition of Harris Tweed became statutory and forever tied the cloth to the Islands. In essence, Harris Tweed means a tweed which has been hand woven by the islanders at their homes in the Outer Hebrides, finished in the islands of Harris, Lewis, North Uist, Benbecula, South Uist and Barra (The Outer Hebrides) and made from pure virgin wool dyed and spun in the Outer Hebrides. Only cloth that fully conforms to this definition is entitled to bear the world famous “Orb” trademark which was granted to the islanders in 1910.

For such a burly and utilitarian fabric, Harris Tweed evokes an a great deal of romantically nostalgic feelings and the BBC4 series certainly captured this notion. The reason being is that the tweed is still woven by pedal-powered looms in the homes of Scottish sheep herders on the outermost fringe of the British Isles, just as it has been since 1846. Over the decades, the process has certainly evolved but it has always remained true to the basic principles which are enshrined, uniquely, in the Act. Today, Harris Tweed is the only handwoven fabric produced in commercial quantities. It once hung in every British wardrobe but with the rise of throwaway fashion all of that sadly stopped. If ever there was a time to wrap ourselves up in this beautiful, sustainable, ethnic British cloth it is now. One of the reasons that make this fabric so special to me is that its relationship with the setting in which it is made. The fabric and landscape are entwined. The myriad of Harris Tweed patterns are inspired by the ever changing landscape...

For such a burly and utilitarian fabric, Harris Tweed evokes an a great deal of romantically nostalgic feelings and the BBC4 series certainly captured this notion. The reason being is that the tweed is still woven by pedal-powered looms in the homes of Scottish sheep herders on the outermost fringe of the British Isles, just as it has been since 1846. Over the decades, the process has certainly evolved but it has always remained true to the basic principles which are enshrined, uniquely, in the Act. Today, Harris Tweed is the only handwoven fabric produced in commercial quantities. It once hung in every British wardrobe but with the rise of throwaway fashion all of that sadly stopped. If ever there was a time to wrap ourselves up in this beautiful, sustainable, ethnic British cloth it is now. One of the reasons that make this fabric so special to me is that its relationship with the setting in which it is made. The fabric and landscape are entwined. The myriad of Harris Tweed patterns are inspired by the ever changing landscape...

The beautiful, ever changing landscape inspires the famous cloth.

In a previous post, I discussed how 2010 was make or break time for Harris Tweed. It is one of the most iconic fabrics in the world yet, as the Tweed series documented (if you missed it, it is available over on Vimeo) the outlook for the fabric was similar to the weather forecast for the Outer Hebrides in Winter, not all that sunny and bright. The BB4 series looked at the island industry in decline. With the closing of its largest mill, it was crunch time for the business. The story weaved of the British Isles most notable native cloth was both wonderful and frustrating. Thankfully, since the series ended there has been something of a revival and recovery shoots were now visible through the landscape hinting of a great green future. As the outside world is cottoning on, mood on the island has radically shifted and the weavers are busy. Life on the island is so much better and with Macualey as our guide, we saw the revival firsthand.

Following a tasty breakfast including the famous Stornoway black pudding, our whirlwind day began with a with a visit to Harris Tweed Hebrides, the award-winning company based at Shawbost on the west coast of the Isle of Lewis. The mill now accounts for more than 90 per cent of Harris Tweed production. The company was named Textile Brand of the Year 2009 at the Vogue.com Scottish Fashion Awards and given the major accolade for Outstanding Contribution at the 2009 Scottish Style Awards. The mill use a range of more than one hundred yarns which can be made up into thousands of patterns by our highly skilled workforce. They represent generations of experience in this craft industry and it was a pleasure to see them in action.

Visiting the largest mill, Harris Tweed Hebrides

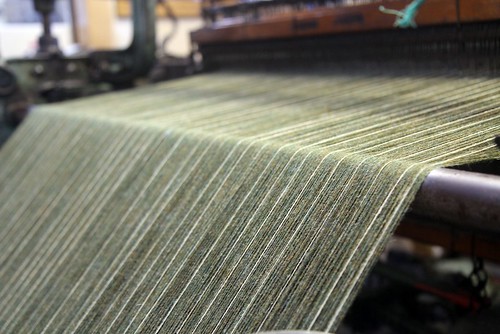

The Harris Tweed story begins with pure virgin wools which are blended together to gain the advantages of their unique qualities and characteristics. Although most of the wool is grown principally on the Scottish mainland, in the early summer the island communities join together to round up and shear the local sheep which are dotted throughout the landscape. Once sheared the wool is taken to the factories of the main tweed producers where is is washed and then dyed. The coloured and white wools are weighed in predetermined proportions and then thoroughly blended then carded. The resultant yarn has a twist imparted to it as it is spun to give it maximum strength. The spun yarn is then warped. The warping process is vitally important process where the basic pattern is prepared by winding the threads to ensure an even tension throughout. The warp is then gathered in long hanks...

Documenting the initial mill processes. From raw material to processing and warping.

The warp is then delivered or collected, together with yarn for the weft, to the weavers. As described above, all Harris Tweed is hand woven on a treadle loom at each weaver's home. The relationship between the mill and the weaver is central to the production of Harris Tweed. Now, there are approximately one hundred and twenty active weavers but few are as famous or as well respected as Donald John MacKay. Don John is an independent weaver and has been at the forefront of the Harris Tweed revival in his far flung, remote outpost. He buys the yarns off a mill to fulfil his own tweed orders as opposed to being contracted by a mill to weave the cloth for them. Don John can work independently and create a business for himself as opposed to many other weavers who rely on the mills to get them business. In this sense, Harris Tweed is truly a subversive cloth as it is made by workers who own the means of production and produce in defiance of the global manufacturing trend. When the tweed enthusiast Patrick Grant of Nortons and Sons requires the fabric he turns to Don John.

Back in September 2004, MacKay and his wife, Maureen, were approached by the Harris Tweed Association on behalf of the sportswear giant Nike to produce a couple of metres of cloth. The duly sent a few samples of work to Nike's American headquarters and it soon snow balled in to the first full collaboration between the parties. Six years on and Nike have once again turned to the respected craftsman and we were invited in to the cramped confines of his eighteen foot by fourteen foot shed on the picturesque island of Harris. It is remarkable to see a multi national company like Nike work so closely with a single craftsmen. It is this dichotomy which makes this collaboration so covetable...

Back in September 2004, MacKay and his wife, Maureen, were approached by the Harris Tweed Association on behalf of the sportswear giant Nike to produce a couple of metres of cloth. The duly sent a few samples of work to Nike's American headquarters and it soon snow balled in to the first full collaboration between the parties. Six years on and Nike have once again turned to the respected craftsman and we were invited in to the cramped confines of his eighteen foot by fourteen foot shed on the picturesque island of Harris. It is remarkable to see a multi national company like Nike work so closely with a single craftsmen. It is this dichotomy which makes this collaboration so covetable...

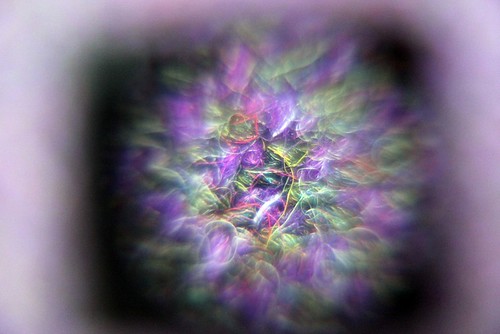

Exploring Don John's intimate space and chronicling the weaving process on his pedal powered single loom. The final image which shows a magnified look at the cloth really captures the beauty of my tweed.

The tweed returns to the mill in its 'greasy state' and here it is finished. Dirt, oil and other impurities are removed by washing. The tweed then passes through the nimble and skilled hands of of the mending department where any loose ends and broken threads are rectified. This stage is an essential quality control activity and ensures that there are no imperfections. Various finishes can then be applied to the tweed. The final process is the examination by the independent Harris Tweed Authority, before application of the famous “Orb” trademark which is ironed on to the fabric as the ultimate seal of approval.

The finishing guarantees the utmost quality before the official stamp is ironed on.

Throughout the day, it was a pleasure to be able to show the finished shoe (that we were generously gifted) to the individuals who had helped make them. Both the mill workers and Don John gave the finished article their enthusiastic thumbs up. Each loved the finished design and were so pleased by the prominent Harris Tweed branding. The fruits of this collaboration, the Nike Sportswear x Harris Tweed Air Royalty Vac Tech shoes are of course now available from Offspring, 1948 and NikeTown London. The shoe features the trademark Harris Tweed material on the upper paired with a premium brown leather toe box and heel giving a quintessentially modern British look. The Swoosh is subtly hidden within the luxury cloth now appearing embossed and the tongue carries the signature Harris Tweed logo replacing the traditional Nike Sportswear logo. Adding to the design are tweed rope laces to give an outdoor inspired feel. They cost £75 only a limited run is available, so be quick if you fall for their charms.

Now, we couldn't resist braving the elements to take a few outfit shots in the beautiful setting. Despite the with bracing cold winds we had a lot of fun posing in front of the stunning environment. From the Callanish Stones (which we were told are actually older than Stone Henge) to the beaches of Harris we explored it all...

Braving the coastal chill in Stornoway. Nike Sportswear x Harris Tweed Air Royalty Vac Tech worn with Creep by Hiroshi Awai shirt, wool trousers from Uniqlo and crombie by ASOS.

The beautiful beach of Harris. Nike Sportswear x Harris Tweed Air Royalty Vac Tech worn with Creep by Hiroshi Awai shirt, wool zip scarf by Braille, wool trousers from Uniqlo and Crombie coat by ASOS.

______________________

I hope the post demonstrates that at the very heart of Harris Tweed, there is an ability to combine centuries of tradition and heritage with creativity and a defiant sense of individuality. Hopefully the images capture the wonders of this cloth and the setting that is so integral to it. Having only returned on Monday night, I still long to go back. The glorious landscape and fabric are undeniably interwoven. Hopefully we will see an infestation of the flights that leave Edinburgh and Glasgow so that people can explore the scenes. It is breathtakingly beautiful – on Harris in the summer, turquoise waves lap on empty white beaches. Go in autumn or spring and you’ll never want to leave, and being there forces you to want some of it on your back. I’ve never come across another fabric that I lust after. It is wonderfully unique and this collaboration celebrates it so well. Here's hoping that this is just the beginning of a new era of Harris Tweed.

No comments:

Post a Comment